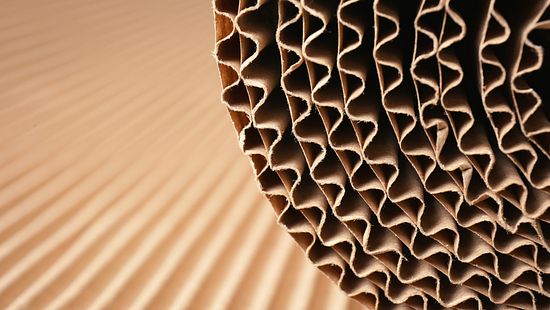

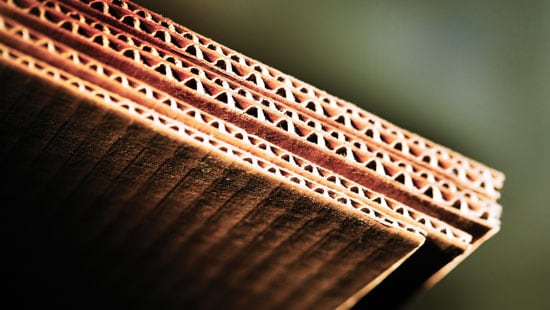

Board and Packaging

Nalco Water is a global leader in providing comprehensive process and water treatment programs for the board and packaging industry value chain. Our mission is to deliver safe, reliable, innovative solutions that enhance operational efficiency, minimize input costs, and provide fiber-based product functionality that support our customers' packaging and sustainability goals. By leveraging a combination of mechanical, chemical and digital solutions, our offerings minimize the need for over-engineering the finished sheet and ensures the operation and product quality is optimized for success.

Explore Our Interactive Paper Mill

METRIX™ Horizon

More strength. Less Weight.

Differentiate your product with METRIX Horizon, Nalco Water’s newest dry strength technology for recycled paperboard, and give your customers stronger, lighter paperboard packaging to help achieve their sustainability goals and improve costs.

Improved Sizing Efficiency in Paper and Paperboard

NALSIZE™ Tiger High Performance ASA technology delivers stable, controllable, on-machine sizing. This sizing efficiency reduces chemical requirements and energy use.

Nalco Water 4D Air™ Program

Nalco Water’s 4D Air Program uses chemicals for paper and packaging to reduce the effects of entrained air and surface foam in the carton and container board market.

Delivering Innovation and Expertise to the Board & Packaging Industry

Our approach sets us apart. With an unparalleled commitment to personally delivered service and a suite of innovative technologies and science-based solutions, we drive positive economic and sustainable impacts through our customers operations, and the communities in which they operate.

Board & Packaging Case Studies

Metrix™ Horizon Delivers Strength & Productivity for North American Recycled Containerboard Producer

Read how METRIX Horizon delivered improved containerboard strength, reduced refining and increased speed resulting in reduced energy and greenhouse gases and $3.1M total value delivered.

High Performance Linerboard Mill Implements METRIX™ Technology

Learn how Nalco Water’s METRIX Technology helped a mill obtain environmentally sustainable results of reduced basis weight and increased production.

Increase Production and Improved Wet- End Stability

Read how High-Performance Linerboard & Medium Mill Incorporates Core Shell™ 61067 Technology and POSITEK™ 4G 9000 Technology Through PARETO™.

New HYBRID™ technology saves more than $700,000 annually at Gypsum Liner Mill

Learn more about how today’s gypsum liner paper machines are solving their challenges with Nalco Water production aids for packaging.